December, 2016 News

2016 AGM

Thanks to the 38 members who sent in their proxies. You outnumbered the 28 actual bodies who attended! It was a successful meeting and we were able to clarify a number of points particularly in regard to financial matters.

The Executive and Committee of Management are the people who put personal statements in the October newsletter. An election was not necessary.

Charles Cull was awarded Life Membership: Charles recently completed 15 years of active work service in the hangar. He is the man responsible for our working exhibits of the Norden bombsight, the radar and the wireless.

Charles receiving his award from Lyn Gorman (Pres.)

Ken Hindle and Doug Sinclair, the driving forces behind the Oxford replica, were named joint recipients of the Ken Bullen Award. Not possible to split the two on commitment and work ethic. Even though they work in timber I’m sure Ken Bullen would approve their selection.

Doug receiving the Ken Bullen Award for the Oxford “boys”.

Vern Roberts asked to address the meeting to convey, on behalf of all those who began the project in 1988, appreciation to all those who have continued on with the work.

And we all enjoyed the light luncheon and discussion after the meeting. Thanks to the people who supplied the food.

Liberator Update (John Morrissy)

Work accomplished 2016

- Fuselage:

The installation of the saddle section has progressed over the year. The work has required the fitting of brackets fore and aft of the section to attach the saddle to the fuselage frames. This work has been done in the confined space over the wing. The saddle fuselage joints are covered by external straps. The front one is in place and a new rear one is being made.

The bomb bay doors have the required remake of top and bottom edges to allow free movement of doors when raised or lowered. A new cable operating system has been installed and the doors are now manually operable. Power operation awaits rebuilding of the hydraulic system…..a work in progress.

Hydraulic system piping installed in the forward starboard side has been removed, inspected, cleaned, repaired (or new replacement sections made) and reinstalled along with refurbished support brackets.

The oxygen system component installation continues with additional pipe fittings being sourced.

- Armament

The installation of the rear turret moulded perspex shell and gun side blisters is progressing. The sliding doors at the rear are fitted and operate easily.

The front Emerson display turret had the gun elevation drive removed to correct a problem with the clutch mechanism for power to manual operation. This has been rectified and the mechanism reinstalled. The azimuth and elevation controls now work. The turret perspex will be reinstalled before it is returned to Graeme for installation of perspex shell, doors and other internal fittings.

Bomb aiming and release systems components in the bomb bay have been installed on the forward rack along with the rod linkage and support brackets. A lack of parts will require some new components to be made. This includes the bomb control quadrant (we’ve searched EVERYWHERE for one!) in the forward fuselage.

- Controls, Flight Surfaces

The tab control housing and mechanism has been rebuilt and installed on the pilot’s pedestal. A new control wheel is required along with perspex switch guards. The pulley brackets for tab control cables are in place.

Existing flight control cables are in place up to the bomb bay. These have been inspected; some are reusable, others will be replaced. Forward of the bomb bay new cabling is required. Pulley brackets for the flaps are installed but require correct sized AN specification bolts.

- Wing

The port underside of the centre wing panel has been reskinned and is now drilled for the screws which attach access panels.. Gang channel has been sourced from a US supplier for the reskinned section and to replace other corroded sections. Work on fitting panels is dependent on cleaning and preserving the internal wing surfaces.

Number 4 engine rear nacelle frames have been rebuilt and fitted with existing panel sections. New lower and side panels to fit the nacelle frames are being made. The work has identified some issues for the installation of port side nacelles. Engine mounting frames are fixed to the wing using threaded bolts ( non hi tensile) and will need to be replaced with correct AN spec. bolts if the engines are to be run.

- Electrical

The internal lighting system has been installed in the fuselage and is working. Main bus components (Terminal blocks) are installed. Bus wiring is currently being installed. Navigation lighting on the top and bottom of

the fuselage is installed and associated wiring looms run back to the cockpit.

------------------------------------------------------------

Oxford Update

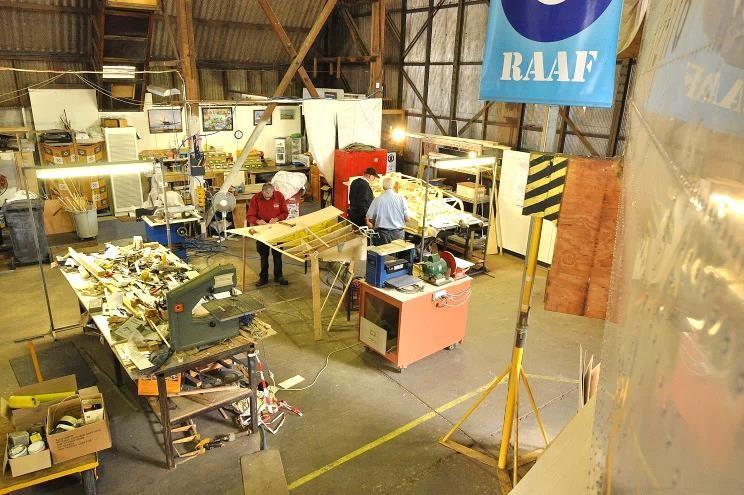

The Oxford crew consists of Ken, Doug, John, Alan and Les; not a large number when you consider the work they’ve done.

Doug and Alan have worked on the port wing. (That’s the left one for those technically challenged like me!) They started from scratch and are now about 70% complete. At the moment they are working on the aileron. A cold moulded surface was formed to receive the aileron. It’s being covered in fine, “bendy” ply. Once that’s finished the control cables will be sourced and fitted along with pulleys and other assorted hardware.

Doug working on the aileron, port side

Ken and John have spent the year working on the starboard side of the wing section. It’s a complicated job and they have made 3 attempts at getting it right. The third try seems to be successful.

Where Ken and John toil.

Les is working alone also on a very complicated piece of the plane. The plans are VERY involved. He’s making the cockpit floor also from scratch and is making steady progress.

Our keen Oxford supporter has been extremely generous in financially supporting this replica. Our thanks to him.

When you look at these pictures it’s easy to see why the Liberator is in their way.

------------------------------------------------------------

End of Year Break.

The hangar will close to visitors 3.30 Thursday 15th December 2016 and re-open Tuesday 10th January 2017.

If you have interstate or international guests and wish to visit the hangar phone the Secretary and I’ll try to arrange to open the hangar for you…..no guarantees.

Pictures

Had a visitor in the hangar from Sydney. He kindly offered to take the group photo as well as the ones of the Oxford and Liberator. Thanks Paul and son Harrison.

Random “Stuff”

Clear access has now been made to the rear of the plane so you can actually see inside the back. This is the view forward from the waist gunner’s window.

In the past 6 weeks we have hosted 3 cub/scout groups, the Porsche Club, the BSA motorcycle club, a couple of Men’s Sheds, a Wyndham History group and kids from a special school. We are diverse.

And to make you smile: Jokes about German Sausage are the wurst…….Venison for dinner again: oh deer!

Happy Christmas

and a great

New Year

from

The Hangar Crew

To all our members